Blueprinting Automation That Makes Warehouses Flow

Value-Stream Maps That Include Feet-Per-Pick

A value-stream map that ignores distance hides wasted time. Add feet-per-pick, typical acceleration, and lift-truck turning radii to your diagram, then model congestion hotspots at receiving, decant, and pack-out. We once cut travel by twenty-eight percent simply by inverting a staging sequence and widening a pinch point by ninety centimeters. Post your toughest layout knot below; we will propose a quick experiment to validate a better path and quantify real impact before heavy investment.

Zoning That Earns Every Square Meter

Define clear purpose-built zones for fast movers, returns triage, value-added services, and replenishment to reduce cross-traffic. Anchor each zone with unambiguous interfaces and measurable handoffs, such as maximum queue length or cycle-time envelopes. In one mid-sized facility, labeling two micro-buffers for late-stage kitting eliminated recirculation loops that swallowed hours daily. If you are struggling with seasonal spikes, try temporary pop-up zones with mobile equipment, then measure their stability. Report your observations so we can calibrate buffer sizes together.

Aisle Geometry for People, AMRs, and Lift Trucks

Aisle width, intersection angles, and one-way rules determine usable throughput more than most realize. Combine pedestrian lanes, AMR passing bays, and fixed yield points to lower near-misses and idle time. A pilot using one-way diagonals cut conflicting moves by nearly half while maintaining pick density. Test alternative geometries with cones and temporary signage for a week, then compare heatmaps of stops, reversals, and delays. Share the heatmaps, and we will help interpret patterns that justify permanent changes.

Choosing the Right Mechanization Mix

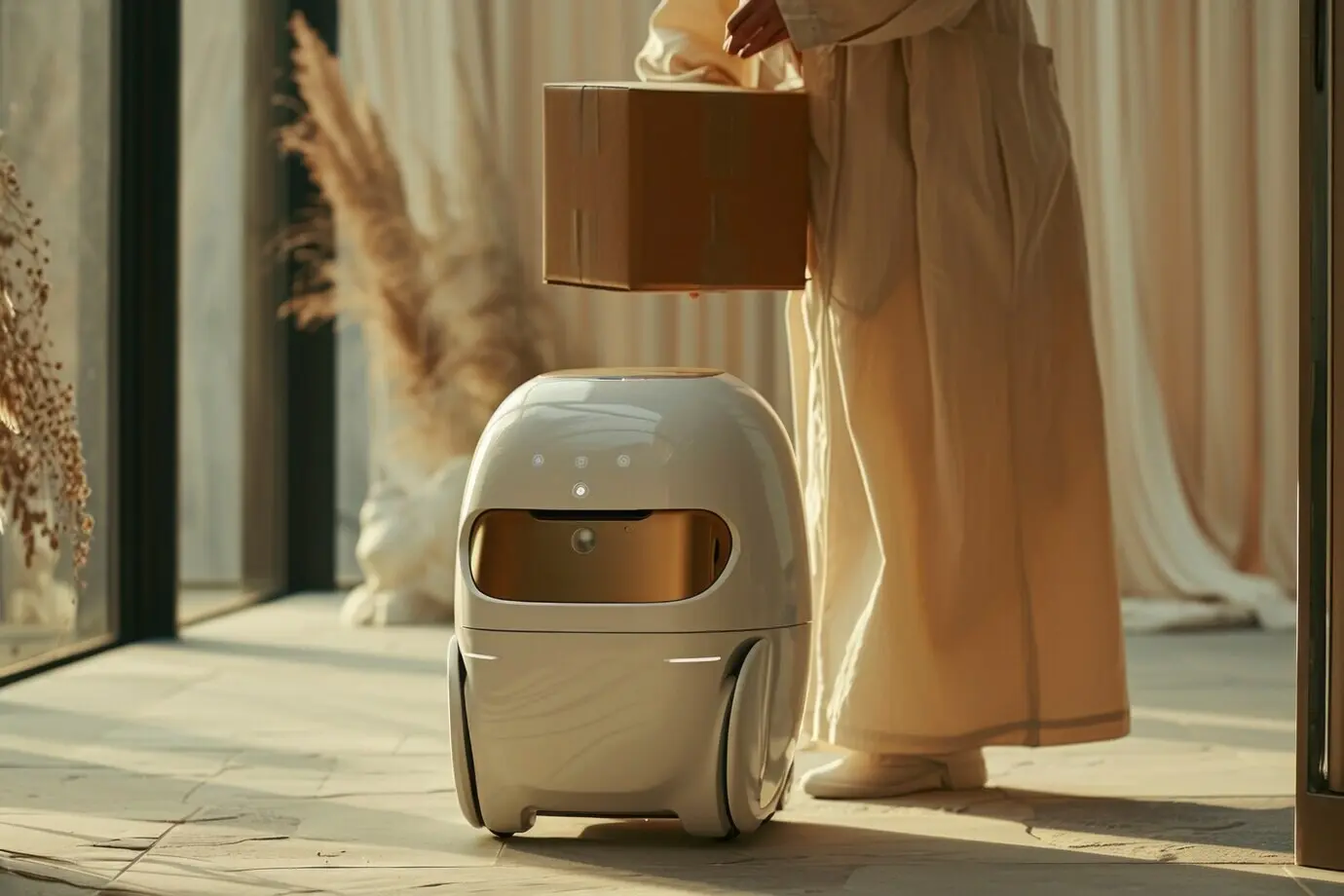

AMRs for Dynamic Travel and Late Binding

Autonomous mobile robots shine when orders fluctuate and travel paths constantly change. They let you postpone decisions until the last responsible moment, balancing waves and priority orders without tearing up conveyors. Plan charging islands, safe passing pockets, and firmware update windows within regular shifts. In one consumer goods operation, AMRs absorbed a surprise promotion without overtime by elastically retasking routes. Share your peak-to-average ratio and aisle widths, and we will estimate a safe fleet size with contingency buffers.

Conveyors and Sorters for Predictable Cadence

Conveyors enforce rhythm and unlock high-speed sortation, especially for stable carton flows. The trade-offs include fixed paths and longer changeover times. Design divert points where manual bypass remains practical, and specify sensor coverage for jam detection that triggers humane slowdowns rather than abrupt stops. A compact shoe sorter rescued Saturday backlogs for a 3PL by smoothing releases. If you are considering hybrid strategies, describe your order profiles; we will identify zones where conveyors outperform flexible options without creating brittle dependencies.

Shuttle Systems When Density Rules Everything

Shuttles offer dense storage and rapid sequencing, shining when space constraints collide with service promises. They require careful maintenance planning, spares kits, and clear rescue procedures for stalled carriers. Model warm, cool, and peak scenarios to validate dwell-time assumptions. One apparel client doubled line throughput after re-slotting fast movers closer to induction. Ask about shuttle lift redundancy and lane balancing; we will share a preflight checklist covering spare positions, diagnostic telemetry, and swap times to protect uptime and service levels.

Interfaces That Fail Gracefully

Real-Time Prioritization Beats Perfect Schedules

Digital Twins That Shorten Commissioning

Safety, People, and Regulatory Confidence

Collaborative Robot Safety Without Slowing Flow

Ergonomics That Cut Injuries and Pick Errors

Data-Driven Slotting and Capacity Truth

{{SECTION_SUBTITLE}}

Velocity Models That Survive Promotions

Affinity Mapping That Reduces Touches

Pilots That Pay for Themselves

Commissioning Checklists That Catch Ghosts

Scaling Rules That Prevent Brittle Growth