From Static Shelves to Smart Systems

Reading the Building: Constraints, Capabilities, and Hidden Potential

Structural and Utilities Reality Check

Process Mapping That Honors Everyday Work

Risk Register That Guides Intelligent Trade-offs

Pilot Cells That Prove Value Fast

Select a pain point with measurable waste, like long walk time between pick zones. Deploy a minimal AMR shuttle loop or pick-to-light bay inside portable fencing. Define success as reduced touches, shorter cycle time, and fewer errors. Instrument everything, compare baselines, and run A and B shifts. Capture operator feedback daily, then tune paths, slotting, and replenishment cadence. When the data sings, extend hours, add vehicles, and replicate the pattern. When it stumbles, iterate swiftly without reputational scars.

Orchestration Layer as the Backbone

A warehouse execution or control layer harmonizes orders, inventory, and machine tasks without ripping out the core WMS. Robust APIs, message queues, and device adapters allow different vendors to coexist. This orchestration assigns work to people and robots, throttles release waves, and prevents aisle congestion. It also enables graceful degradation when subsystems hiccup. By investing early in orchestration, you avoid brittle point integrations, preserve vendor optionality, and gain the freedom to scale technologies as needs and economics evolve.

Change Windows and Parallel Running

Plan upgrades like air traffic control: scheduled downtime, rollback checkpoints, and staffed war rooms. Use parallel running to validate automated outputs against manual processes under real load. Stage inventory and define fallbacks for every cutover step. Communicate broadly with supervisors, drivers, and carriers, publishing clear expectations and escalation paths. After go-live, hold daily retrospectives to capture wins and address friction. These rituals harden confidence, protect customers, and transform each phase into a repeatable playbook for future extensions.

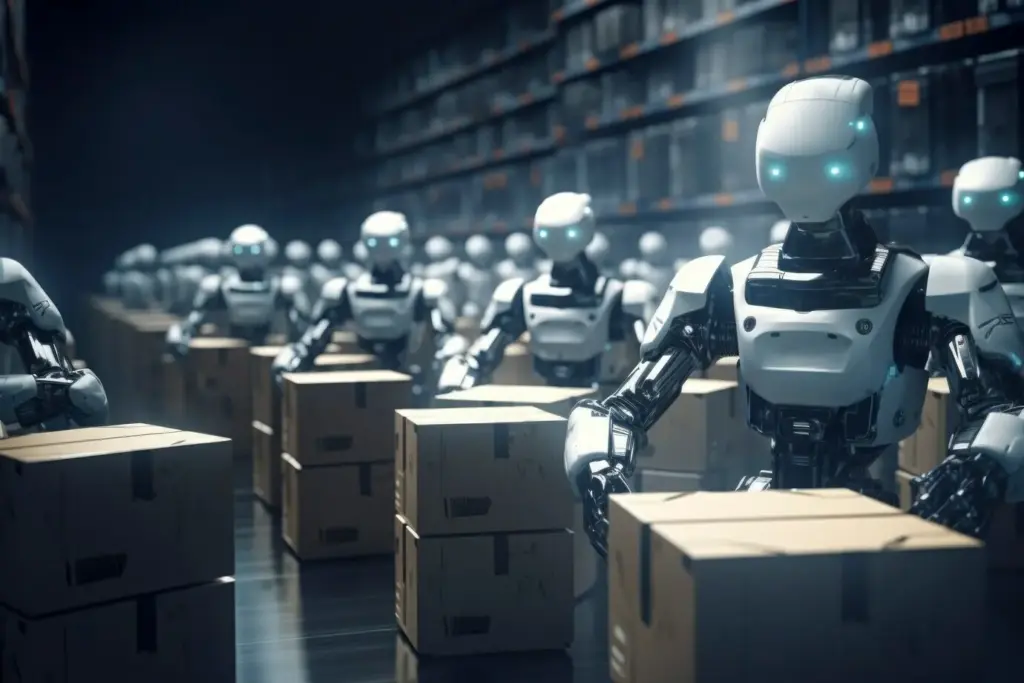

AMRs and Totes: Flexible Movement Without Rails

Autonomous mobile robots weave safely around people and pallets, guided by lidar, cameras, or markers. Start with simple milk-run routes, then graduate to dynamic task allocation through a fleet manager. Standard totes, staging shelves, and modular waypoints keep costs tame. Plan charging islands near idle zones and monitor battery health closely. Integrate with pick stations for hands-off transport. When volumes rise, add vehicles, zones, and missions rather than replacing infrastructure, preserving agility while multiplying labor productivity and order consistency.

Goods-to-Person Micro-Stacks

Mini-load shuttles, vertical buffer modules, or robotic cube stores deliver items to ergonomic stations without massive civil works. Begin with a single aisle or module connected to high movers, then loop in medium movers as ROI proves out. Blend carton flow for surges and bulky items. Keep maintenance paths accessible, spare parts organized, and software tuned to demand shapes. Operators benefit from reduced walking, predictable workflows, and safer motions, while cycle times shrink and slotting becomes a continuous, data-informed practice.

Vision-Driven Picking That Learns Quickly

Modern cameras and machine learning recognize diverse packaging, barcodes, and textures, guiding lights, displays, or robot grippers. Start with assistive vision at manual stations to raise accuracy and reduce training time. As confidence grows, introduce robotic picking for stable SKUs and repeatable grips. Continuously retrain models using mis-picks and edge cases captured in production. Measure confidence thresholds, dwell times, and exception rates. Results compound as operators trust the guidance, audits shrink, and customers receive orders that match exactly what they expected.

Upskilling Journeys That Respect Experience

Safety by Design, Not Afterthought

Communication Rituals That Keep Momentum

Data Plumbing: Integrations That Survive Reality

Economics That Stand Up in the Boardroom