Wiring the Warehouse: Systems, Robots, and Sensing Working as One

Canonical data and contracts

Events, streams, and time

Aligning WMS and ERP Without Friction

One source of inventory truth

Establish ownership for quantities by status, lot, and location, then automate reconciliation between cycle counts, robot telemetry, and shipping confirmations. When discrepancies occur, route them through workflow with business priorities. A single inventory truth prevents double promising, accelerates ATP, and shortens customer service resolution during seasonal pressure.

Orders, promises, and waves

Establish ownership for quantities by status, lot, and location, then automate reconciliation between cycle counts, robot telemetry, and shipping confirmations. When discrepancies occur, route them through workflow with business priorities. A single inventory truth prevents double promising, accelerates ATP, and shortens customer service resolution during seasonal pressure.

Financial hooks that still flow

Establish ownership for quantities by status, lot, and location, then automate reconciliation between cycle counts, robot telemetry, and shipping confirmations. When discrepancies occur, route them through workflow with business priorities. A single inventory truth prevents double promising, accelerates ATP, and shortens customer service resolution during seasonal pressure.

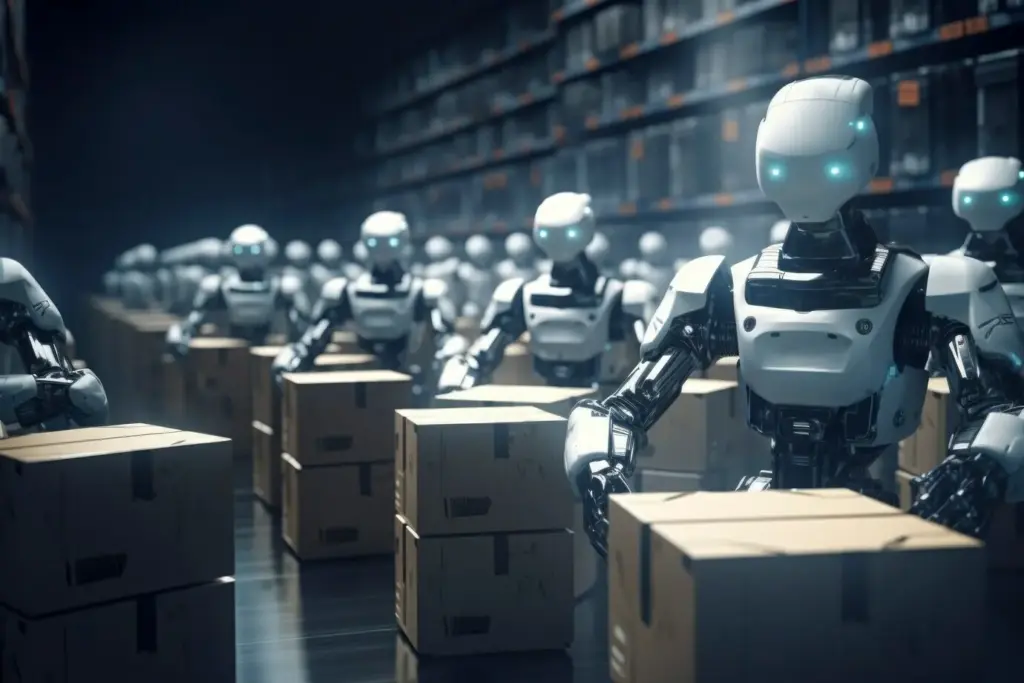

Orchestrating Robots with Confidence

IoT Sensing that Illuminates Decisions

{{SECTION_SUBTITLE}}

Placement strategy, not gadget scatter

Edge computing that respects latency

Planning, Simulation, and the Digital Twin

Security, Reliability, and Change That Stick

01

Segment, authenticate, observe

Segment warehouse networks by function, require mutual TLS for services, and rotate secrets automatically. Baseline normal traffic between WMS, ERP, robots, and sensors, then alert on deviations. Observability must tie into business KPIs so engineers know whether an alarm risks orders, safety, or only a redundant pathway.

02

Resilience under pressure

Design for graceful degradation: cached worklists, local decision loops, and offline modes for inbound and picking. Practice failovers during working hours, not midnights. Keep spare endpoints ready for vendor outages. When something breaks, customers should notice faster deliveries, not the heroics hiding your recovery work.

03

People, pilots, and adoption

Pair engineers with supervisors to co-design procedures, signage, and quick aids. Run short, reversible pilots with clear exit criteria and celebrate operator feedback. Training sticks when it solves a daily frustration. Invite comments below, share your lessons learned, and subscribe to follow the next build in this series.